We are committed to constant innovation, doing our part every day to support environmental and social sustainability. We stay focused on our responsibility to use energy wisely and promote sustainable development.

Sustainabilty

FROM WASTE TO RESOURCE

Every day, we strive to minimize material waste by carefully studying the best ways to optimize formats and reduce offcuts to a minimum.

None of the leftover materials from our metalworking processes are discarded. Instead, they are meticulously sorted and entrusted to reliable partners. These partners ensure that the materials are given a new life, being 100% recycled through pre-treatment and melting processes to create new raw materials for future products.

REDUCE COSTS, MAXIMIZE QUALITY = INNOVATION

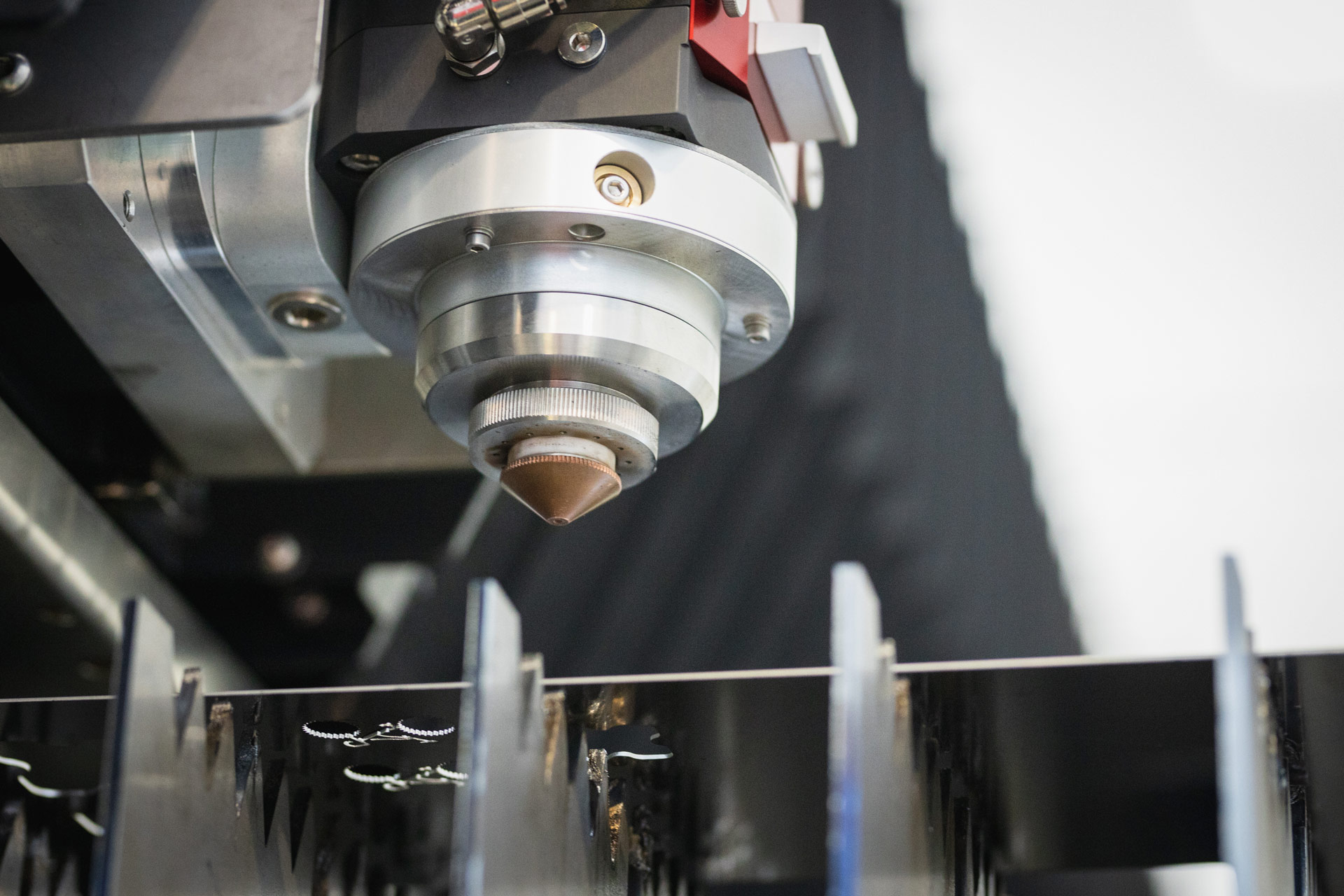

Most of the production waste in our workshop comes from sheet metal cut using our new fiber laser cutting system.

In 2023, we replaced our old, energy-intensive CO2 laser cutter with the new Cultlite Penta fiber laser machine. This upgrade allows us to benefit from the significant advancements in technology, fully aligning us with Industry 4.0 standards. The new machine delivers far superior cutting quality, significantly reduces production time, and, most importantly, drastically lowers energy consumption.

The previous CO2 laser cutter required multiple gases: nitrogen and oxygen for cutting assistance, as well as helium and carbon dioxide to generate the laser beam. It consumed an average of 15 kWh even when on standby.

The new fiber laser cutter is a game-changer. It delivers much more effective power for processing (8,000 watts) while maintaining the same electrical input during peak operation, and it consumes an average of just 2 kWh.

On the gas front, we’ve adopted a cutting-edge method that uses compressed air as the cutting assist gas.

To further enhance sustainability, the compressor, the fiber laser machine, and all other equipment in our workshop—including power tools, computers, and lighting—draw electricity from our newly installed photovoltaic solar panel system.

SUNLIGHT: OUR SOURCE OF CLEAN ENERGY

In the summer of 2022, we installed a photovoltaic system on the roof of our workshop with a capacity of 70 kWh.

The structure’s longitudinal orientation points directly south, and the panels were mounted on surfaces inclined at a 30-degree angle. These features, combined with the high quality of the panels and today’s advanced technology, allow us to produce an energy surplus beyond what our machines consume.

This surplus enables us to be CO2 neutral, actively contributing to the ecological transition and paving the way for a future free from fossil fuel consumption.

Every 12 months:

34.65 tons

of coal saved

41.81 tons

of CO2 not emitted

56,79

equivalent trees planted

AVOIDING MISTAKES AND SAVING TIME, OTHER FORMS OF SUSTAINABILITY

Laser Tube Cutting:

allowing us to shape and cut round and rectangular tubes with precision and speed. This enables the creation of pieces in infinite shapes and configurations. The speed and accuracy of this process are remarkable, opening up an incredibly broad range of execution possibilities.

Laser Welding:

The latest welding technology is now available in our workshop. A fiber laser beam is directed through a special torch capable of welding different materials together, producing pristine, ultra-thin, visually appealing weld seams with minimal thermal distortion—something unimaginable with traditional welding technologies like TIG, MIG, electrode, or oxyacetylene flame.

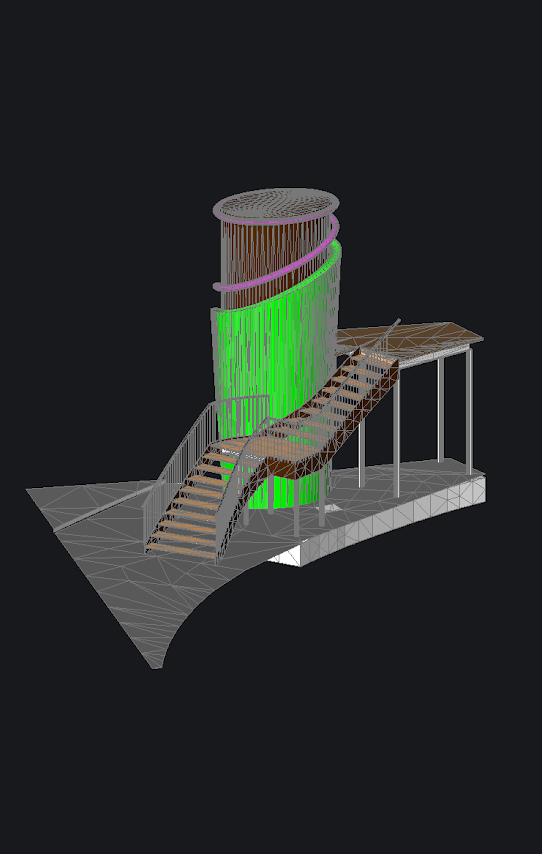

3D Software:

Thanks to these advanced tools, our project managers can fully leverage the capabilities of 3D design using software like Advance Steel (an extension of AutoCAD) and SolidWorks.

For the world of windows and doors, all production is managed through FP Pro.

As for measurements, we utilize 3D technology through a laser measurement system that provides highly accurate data, directly viewable on a monitor.

SOCIAL RESPONSIBILITY

Beyond our daily work, we are proud to support an important local organization.

The Croce Verde – “Volontari del Soccorso Cavallino-Treporti” O.D.V. has been helping our community for over 40 years, providing first aid day and night to residents, visitors, and tourists. This is especially important since our area is the fifth most visited in all of Italy.

We gladly offer our time, spaces, and some equipment to help the association with training sessions, logistics, and various maintenance activities.

We are proud to support this active organization, which provides one of the most important services of all: protecting the health and safety of everyone, especially in emergencies.

Logistical support

Collection center

Events

Free maintenance of transport vehicles